There are more turbo-charged vehicles on the road than ever before. More than 25% of new vehicles in the U.S. got turbos in the 2017 model year. What’s not to love? A turbo can help add power to your engine and increase fuel efficiency. But turbocharged diesel engines require special care and consideration. If you fall behind on regular turbo maintenance, you’ll need to replace your diesel turbochargers altogether, which can cost thousands of dollars. Rebuilding the turbo from scratch is another option, but you’ll need to contact your local mechanic.

The good news is that turbo charged engines don’t usually require any more maintenance than naturally aspirated engines, except for additional oil changes and changing the spark plugs. However, the more you use the turbo, the more you’ll need to maintain it. Use these four diesel turbo maintenance tips to keep your engine running as smoothly as possible.

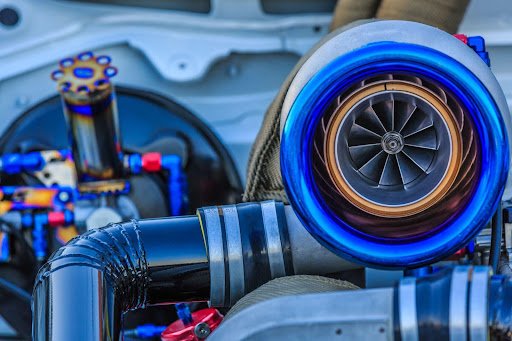

What is the Turbocharger?

The turbocharger is a deceptively simple device. It’s made up of two finned wheels that spin together on a shaft that sits between the engine and exhaust. The hot side of the turbine wheel captures the power of the exhaust, while the cold turbine wheel forces this energy back into the engine for an additional surge of power. When the turbo is not in use, the turbine spins along as normal without generating excess power.

As simple as this device may seem, replacing it or rebuilding the turbo from scratch can be a lengthy, expensive process. Most turbos are variable geometric turbos, which means they use a sliding vane or sleeve to adjust the amount of exhaust gas driving the turbine wheel. This part is one of the first to go, especially on the 6.0L engine. Find replacement 6.0 VGT actuators to resolve the issue.

How to Maintain Your Turbo:

Consult the Owner’s Manual

Turbo engines require specific care and attention. The best way to maintain your turbo is to give it what it needs. Look up your owner’s manual and avoid using anything other than the manufacturer’s recommended motor oil. Keep up with the engine’s recommended service intervals as well to prevent long-term damage.

Oil Up

Turbo engines run hotter than normally aspirated engines. The hot side of the turbine can spin at speeds of up to 100,000 rpm. That can put enormous pressure on your engine’s parts. Every diesel engine needs high-quality motor oil. The oil lubricates these parts to reduce wear and tear, but turbo engines tend to be much harder on motor oil. Turbos have come a long way in recent years as manufacturers found ways to reduce the issue. You can use a water-cooled turbocharger or top-shelf motor oil to increase lubrication, but you will also have to change your oil more often as well.

Consider using oil additives to further increase lubrication. These products help clean the engine while reducing the rate of oxidation. Experts recommend using around 20% or one quart of oil additive for every gallon of plain motor oil. If the engine is badly worn, use up to 60% or 80% if necessary.

You should also make sure the oil has had a chance to reach the turbo before you start mashing your foot against the gas, otherwise, the oil won’t be able to lubricate the turbo, forcing it to run hot and dry.

Fuel Additives

Now that your turbo is slick, make sure your fuel system can handle the journey by adding a fuel additive to your tank. Whether you’re using regular diesel or biodiesel, you should always add the additive to reduce wear and tear. The additive prevents clotting and gelling to ensure an even, all-over spray pattern. The additive should also demulsify water to reduce oxidation. Some additives will try to burn off the excess water using high temperatures, but this can damage the fuel injectors. Your engine comes with a water separator that’s designed to remove the water naturally from the system.

Clean Your Filters

Both the fuel and air filters help keep your engine clean. Dirt and debris will start to clog these filters over time, making it that much harder for your engine to do its job. Replacing and cleaning your filters according to the recommendations will help prevent overheating and unnecessary wear and tear.

Coolant and ECGs

With all that excess heat and friction, you need to make sure your vehicle’s exhaust gas recirculation (EGR) system is working properly as well. The EGR cools the temperature of the exhaust to reduce NOx emissions. Coolant runs up against the fuel mixture while transferring the feat away from the engine and to the radiator. If your EGR system isn’t working, expect your turbo to suffer as a result.

Replace your EGR coolers according to the manufacturer’s recommendations.

Make sure you are using the recommended coolant as well. Mixing coolants is one of the worst things you can do for your engine. The different coolants can cause a chemical reaction inside the EGR system, which is a recipe for disaster.

You should also never use water instead of coolant. If you are stranded on the side of the road and your engine is overheating, water might help you get to the nearest gas station but switch over to coolant as soon as possible.

Treat your turbo with the care and consideration it deserves to increase its working life.